CNC Programming & Master CAM Course

Quick Read About CNC Programming & Master CAM Course

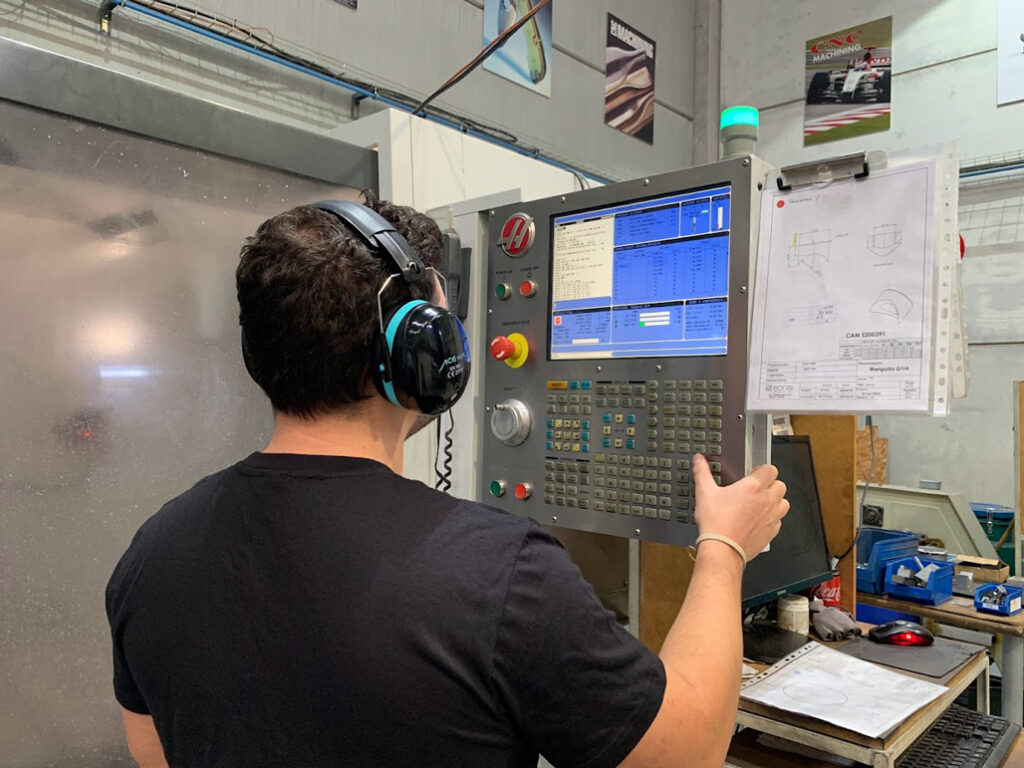

The CNC Programming and Master CAM Course at Ambit Automation offers transformative education in computer numerical control and cutting-edge manufacturing. From precise toolpath creation to hands-on CNC machine operation, this course equips students with the skills essential for modern manufacturing.

What is CNC Programming and Master CAM Course?

CNC Programming and Master CAM Course is a comprehensive training program by Ambit Automation, focusing on Computer Numerical Control (CNC) and Master Computer-Aided Manufacturing (CAM). It covers everything from 2D and 3D design to CNC machine operation, providing a holistic understanding of modern manufacturing.

Ambit Automation: Best CNC Course Training Institute

Ambit Automation stands out as the premier CNC Course Training Institute, offering top-notch education in CNC Programming and Master CAM. With expert faculty, industry recognition, and state-of-the-art facilities, Ambit Automation ensures a dynamic learning environment, preparing students for successful careers in manufacturing.

Introduction About CNC Programming & Master CAM Course

CNC Programming: CNC, or Computer Numerical Control, is a transformative technology that plays a central role in manufacturing processes. It involves using computer software to precisely control the movement and operation of machines, such as mills, lathes, and routers. CNC programming allows for the automated and accurate production of intricate components and products. It has become an indispensable tool in various industries, including aerospace, automotive, and medical device manufacturing. CNC programming is celebrated for its ability to deliver high productivity, reduce the need for manual labor, and generate exceptional accuracy and precision in the manufacturing process.

Master CAM: Master CAM, a key component of our course, is a leading Computer-Aided Manufacturing (CAM) software. It empowers users to transform design concepts into reality with efficiency and precision. By utilizing Master CAM, you can create detailed toolpaths, simulate machining processes, and generate code for CNC machines. This software is widely used in the manufacturing sector to streamline production, reduce errors, and optimize workflow. Master CAM proficiency is a valuable skill sought after by manufacturers worldwide.

Role of CNC in Manufacturing: CNC technology has revolutionized manufacturing by automating tasks that were once performed manually. It controls the movement of machinery with exceptional precision, resulting in consistent and high-quality production. CNC machines can execute complex operations, including cutting, shaping, and engraving, with unmatched accuracy. They are the backbone of modern manufacturing, enabling the creation of intricate parts and components used in various industries.

Importance of CNC: The importance of CNC in manufacturing cannot be overstated. Its benefits include:

- Enhanced Productivity: CNC technology reduces the reliance on manual labor, increasing productivity and efficiency in manufacturing processes.

- Precision and Accuracy: CNC machines deliver precise and accurate results, critical in industries where quality is paramount.

- Cost Efficiency: CNC automation reduces material wastage and human error, leading to cost savings.

- Versatility: CNC machines can be programmed to perform a wide range of tasks, making them adaptable to diverse manufacturing needs.

CNC Programming and Master CAM are integral to modern manufacturing, driving efficiency, precision, and productivity. By enrolling in our course, you’ll gain the skills needed to harness the power of these technologies and excel in the dynamic world of CNC programming and CAM.

Key Highlights & Advantages of CNC Programming Course

Discover the compelling reasons why our CNC Programming and Master CAM Course is the right choice for you:

- Expert Instruction: Benefit from the guidance of an experienced trainer renowned for delivering top-quality CNC training. Our trainer’s expertise ensures you receive the best instruction possible.

- Guaranteed Placement Support: We are dedicated to your success. Our 100% placement assistance program ensures you have the support you need to jumpstart your career in the manufacturing sector.

- Comprehensive 6-Month Duration: Our course spans six months, providing ample time to delve deeply into CNC programming and CAM. This extended duration guarantees a thorough understanding of the subject matter.

- Detailed Syllabus: Before enrolling, review the comprehensive syllabus offered by Ambit Automation. Designed to cover all essential aspects of CNC and CAM, it ensures you gain a holistic understanding.

- Kerala’s Premier CNC Course: Ambit Automation is renowned for offering Kerala’s finest CNC Training. Our commitment to excellence has earned us this distinction, making us a trusted choice in the region.

- TUV SUD Germany Certification: We take pride in our certification by TUV SUD Germany, validating our dedication to delivering top-tier education and training.

- Enhanced Productivity: CNC technology is celebrated for its efficiency, significantly reducing the need for manual labor. By mastering CNC programming, you’ll be equipped to drive higher productivity in the manufacturing sector.

- Precision and Accuracy: CNC production is celebrated for its ability to achieve remarkable precision and accuracy. Our course empowers you to utilize these capabilities to create intricate components with perfection.

- Surging Industry Demand: With CNC technology’s widespread adoption across industries, the demand for skilled CNC operators and programming engineers is growing rapidly. Our course positions you for success in this thriving field.

- Career Advancement: Understanding the intricacies of CNC operation, production metallurgy, and CNC machine operation is pivotal for engineers’ career growth. Our course equips you with the knowledge and skills needed to excel.

Join us on this transformative journey and seize the opportunity to excel in the dynamic world of CNC programming and CAM.

Course Overview – CNC Programming & Master CAM

The CNC Programming and Master CAM Course takes a leading role in this transformation, offering a unique opportunity to excel in modern manufacturing. In an era dominated by automation and digitalization, this course serves as a guiding beacon, illuminating the path to expertise in Computer Numerical Control (CNC) Programming and Master Computer-Aided Manufacturing (CAM). It provides an opportunity to thrive in the dynamic world of contemporary manufacturing.

Course Expectations

As you delve into this educational journey, you can anticipate a comprehensive learning experience that equips you with the skills, knowledge, and confidence necessary to excel in CNC programming and CAM. Throughout the course, you will:

- Master CNC Programming: Attain proficiency in the art of CNC programming, a vital skill in modern manufacturing. Learn how to create precise instructions for CNC machines to craft intricate components.

- Explore CAM Software: Navigate the world of Computer-Aided Manufacturing (CAM) and become proficient in utilizing advanced software tools like Mastercam. Learn how to translate design concepts into tangible products with precision and efficiency.

- Real-World Application: Engage in real-world scenarios and hands-on projects, applying your newfound skills to solve manufacturing challenges and create intricate components with precision.

- Stay Current: Remain up-to-date with the latest trends and technologies shaping modern manufacturing processes.

- Career Readiness: Prepare yourself for a promising career with the confidence that comes from mastering CNC programming and CAM. Be ready to tackle the challenges and opportunities that the manufacturing industry offers.

In a world where precision and efficiency are fundamental to manufacturing success, the CNC Programming and Master CAM Course is your gateway to a prosperous future. Join us on this transformative journey and be prepared to excel in the dynamic world of contemporary manufacturing.

CNC Programming & Master CAM Course Topics

CAD (Computer-Aided Design): CAD, or Computer-Aided Design, is the backbone of modern product design and development. In this module, you will delve into the world of CAD software. You’ll learn how to create precise and intricate 2D and 3D designs that serve as the digital blueprints for manufacturing. This skill is essential for translating creative concepts into detailed designs ready for CNC machining.

CNC Lathe: CNC lathes are fundamental machines in the manufacturing process, particularly for turning operations. In this module, you will gain in-depth knowledge of CNC lathe operations. This includes understanding the machine’s components, tooling, and programming. You’ll master the art of shaping cylindrical components with precision and efficiency, a crucial skill in manufacturing various parts, from shafts to intricate components like bolts and nuts.

CNC Milling: CNC milling is a versatile and essential process for creating complex shapes and components. In this comprehensive module, you’ll explore the world of CNC milling machines. You’ll learn to operate these machines effectively, generate precise toolpaths, and create intricate parts used across industries. This includes understanding different milling techniques, tool selection, and the intricacies of programming CNC milling machines.

Master CAM (Computer-Aided Manufacturing): Master CAM is a leading Computer-Aided Manufacturing (CAM) software that empowers manufacturers to optimize their production processes. In this vital module, you will become proficient in the use of Master CAM. You’ll gain hands-on experience in creating toolpaths, simulating machining operations, and generating G-code for CNC machines. This software is crucial for efficiently translating your designs into the actual machining process, ensuring precision and consistency in manufacturing.

These detailed course topics are designed to equip you with comprehensive knowledge and practical skills in CNC programming and manufacturing. By the end of the course, you will have a strong foundation in CAD, CNC lathe and milling operations, and Master CAM software, setting you on a path to excel in the dynamic world of modern manufacturing.

JOB ROLES AND RESPONSIBILITIES AFTER CNC PROGRAMMING COURSE

List of job roles and descriptions in CNC programming and Master CAM course completion:

- CNC Programmer: Create and edit computer programs that control CNC machines to manufacture a wide variety of products.

- CNC Machinist: Operate CNC machines to produce parts according to CNC programs.

- CAD/CAM Engineer: Use CAD and CAM software to design and manufacture products.

- Manufacturing Engineer: Develop and implement manufacturing processes.

- Quality Control Engineer: Develop and implement quality control procedures.

- Production Manager: Oversee the production process.

- Automation Specialist: Design and implement automated manufacturing systems.

These jobs are all in high demand in a variety of industries, including automotive, aerospace, medical devices, electronics, consumer goods, metalworking, and plastics. They typically offer good salaries and job security.

COURSE CERTIFICATIONS

- TUV SUD International Certificate

- BSS (Govt of India Approved ) Certificate.

Certification Process

The certification process for a CNC programming course typically involves completing a series of exams and/or projects. The exams will test your knowledge of the CNC programming process, as well as your ability to create and execute CNC programs. The projects will give you the opportunity to apply your skills in a real-world setting.

Recognition in the Industry

The TUV SUD International Certificate and the BSS (Govt of India Approved ) Certificate are both highly recognized in the manufacturing industry. These certifications demonstrate to potential employers that you have the skills and knowledge necessary to be successful in CNC programming.

Benefits of Getting Certified

There are many benefits to getting certified in a CNC programming course, including:

- Increased job opportunities: Employers are more likely to hire certified CNC programmers because they know that these individuals have the skills and knowledge necessary to be successful in the field.

- Higher salaries: Certified CNC programmers typically earn higher salaries than non-certified programmers.

- More advancement opportunities: Certified CNC programmers are more likely to be promoted to positions of greater responsibility.

- Increased job satisfaction: Certified CNC programmers are more likely to be satisfied with their jobs because they know that they are skilled and valuable members of the workforce.

COURSE DURATION

6 MONTHS

Placement Assistance

Our commitment to your success extends beyond the classroom. Ambit Automation offers a range of placement assistance services and support mechanisms to enhance your job prospects:

- Career Counseling: Our experienced career counselors are available to provide personalized guidance on your career path, helping you make informed choices.

- Resume Building: We offer workshops and resources to help you create a compelling resume that highlights your skills and achievements.

- Interview Preparation: Prepare for job interviews with our interview coaching sessions. Learn effective communication, interview etiquette, and how to showcase your technical skills.

- Job Listings: Access our network of industry connections and job listings, providing you with access to relevant employment opportunities.

- Placement Drives: Participate in our placement drives, where companies seek to hire our qualified graduates.

- Industry Partnerships: We have partnerships with numerous manufacturing companies, opening doors for potential job placements.

Our commitment to your success is underscored by our strong track record of placing our graduates in reputable manufacturing companies. We take pride in being a stepping stone towards a rewarding career in CNC programming and manufacturing.

Why Choose Ambit Automation for CNC Programming & Master CAM Course

When it comes to choosing the right institution for your CNC Programming and Master CAM Course, Ambit Automation stands out as the ideal choice. With a proven track record of excellence and a commitment to empowering students with the knowledge and skills they need to succeed in the CNC programming and manufacturing industry, here’s why Ambit Automation is the preferred destination for aspiring professionals:

1. Expertise and Reputation:

Ambit Automation has earned a stellar reputation in the field of CNC programming and manufacturing. With years of experience in providing top-notch education and training, we have become a recognized name in the industry. Our institution is known for its:

- Highly Skilled Faculty: Our dedicated faculty members bring extensive industry experience and academic expertise to the classroom. They are passionate about sharing their knowledge and ensuring that students receive the best possible education.

- Industry Recognition: Ambit Automation is widely recognized and respected by manufacturing companies. Our graduates are sought after by employers due to the practical skills and in-depth understanding they gain during their course.

2. Comprehensive Curriculum:

Our CNC Programming and Master CAM Course is carefully designed to cover all aspects of CNC programming, machining, and design. We offer:

- Cutting-Edge Technology: Our institution is equipped with state-of-the-art CNC machines and software, including Master CAM, to ensure that students learn using the latest tools and techniques.

- Hands-On Training: We emphasize hands-on training, allowing students to gain practical experience in CNC machining, 2D and 3D modeling, and CAM programming. This approach prepares graduates to excel in real-world manufacturing settings.

3. Industry Connections:

We have established strong partnerships with leading manufacturing companies, which allows us to facilitate job placements for our graduates. These connections provide you with a valuable advantage when seeking employment opportunities.

4. Alumni Success:

Our alumni have gone on to achieve remarkable success in the CNC programming and manufacturing industry. Their accomplishments serve as a testament to the quality of education and training provided at Ambit Automation.

5. Holistic Learning Environment:

At Ambit Automation, we foster a holistic learning environment that encourages not only technical knowledge but also personal and professional growth. We believe in nurturing well-rounded individuals who are prepared to excel in the competitive world of CNC programming and manufacturing.

Ambit Automation is the preferred choice for individuals aspiring to excel in CNC programming and manufacturing. Our institution’s expertise, reputation, comprehensive curriculum, placement assistance, industry connections, and commitment to holistic learning make us the ideal destination for those looking to embark on a successful career in this dynamic and evolving field. Choose Ambit Automation and take the first step toward a promising future in CNC programming and manufacturing.

Course Benefits and Latest Trends

At Ambit Automation, our CNC Programming and Master CAM Course offers numerous benefits that extend beyond the classroom. We prepare our students for real-world applications by providing them with a solid foundation in CNC programming, machining, and design. Here’s why our course is not only relevant but also aligned with the latest industry trends:

Real-World Applications:

- Manufacturing Excellence: Our course equips you with the skills to excel in the manufacturing industry. You’ll learn how to program CNC machines, create intricate 2D and 3D models, and optimize machining processes. These skills are directly applicable in industries such as aerospace, automotive, medical device manufacturing, and more.

- Precision Engineering: CNC programming and machining demand precision and attention to detail. By mastering these skills, you’ll be prepared to work on projects that require high levels of accuracy, such as creating complex components for aircraft or medical equipment.

- CAM Proficiency: With hands-on experience in Master CAM, you’ll be proficient in Computer-Aided Manufacturing (CAM), enabling you to generate toolpaths, simulate machining processes, and efficiently translate designs into physical objects.

- Versatility: CNC programming and machining skills are versatile and can be applied to a wide range of industries and projects. Whether you’re interested in aerospace, automotive, medical devices, or custom part manufacturing, these skills are in high demand.

Staying Updated with Industry Trends:

- Continuous Curriculum Enhancement: We are committed to keeping our course content up-to-date with the latest industry trends and technological advancements. Our curriculum is regularly reviewed and updated to reflect changes in CNC technology and best practices.

- Integration of Emerging Technologies: We incorporate emerging technologies, such as additive manufacturing (3D printing), Industry 4.0 concepts, and the Internet of Things (IoT), into our course. This ensures that our students are well-prepared to adapt to the evolving landscape of CNC manufacturing.

- Industry Partnerships: Our strong partnerships with leading manufacturing companies provide valuable insights into industry trends and requirements. We leverage these connections to ensure our curriculum remains relevant and aligned with industry needs.

Opportunities

Completing our CNC Programming and Master CAM Course opens doors to a wide range of career opportunities across various industries. Here are some potential job roles and industries where your skills will be in high demand:

- CNC Programmer: As a CNC programmer, you’ll be responsible for creating CNC programs, setting up machines, and overseeing machining processes. This role is crucial in industries like aerospace, automotive, and manufacturing.

- Manufacturing Engineer: Manufacturing engineers optimize production processes, design fixtures and tooling, and ensure quality control. Your skills will be valuable in industries focused on efficient manufacturing.

- CAD/CAM Engineer: CAD/CAM engineers use computer-aided design and manufacturing software to create and optimize product designs and machining processes. They are essential in industries where precision and efficiency are paramount.

- Aerospace Industry: The aerospace industry demands high-precision components, making it a prime destination for CNC professionals.

- Automotive Industry: CNC programmers and machinists are integral to the production of automotive parts and components.

- Medical Device Manufacturing: Precision is critical in medical device manufacturing, and CNC professionals play a vital role in creating intricate medical equipment.

- Custom Parts Manufacturing: Various industries require custom parts and components, creating opportunities for CNC specialists in job shops and contract manufacturing.

- Additive Manufacturing: As 3D printing and additive manufacturing gain popularity, CNC professionals with knowledge in these areas are highly sought after.

Our CNC Programming and Master CAM Course not only prepares you for a successful career but also ensures you stay at the forefront of industry trends. The skills you acquire are in demand across a spectrum of industries, offering you a wide array of exciting and rewarding career opportunities. Join Ambit Automation and take the first step towards a future filled with possibilities in CNC programming and manufacturing.

The highly skilled trainer who is capable of quality CNC training with 100% placement assistance. We conduct 6 months training. Check out the syllabus provided by Ambit Automation before getting admission. CNC Course from Ambit Automation is the best in Kerala. Ambit Automation is the best CNC Training Center Certified by TUV SUD Germany.